Communic84bis's Blog

CRM & Budgeting

1 Comment

Customer Relationship

Management (CRM)

Customer relationship management (CRM) focuses on improving customer service and customer satisfaction in order to retain customers for the foreseeable future. CRM software can be utilised by organisations to be able to better understand their customers, anticipate and respond to customer needs. The idea is to be able to form a bond with customers, which comes across as unique and allows a customer or potential customer to form a positive opinion of your organisation in terms of the high quality customer service provided.

As part of customer relationship management, information regarding the customer will need to be collected on a regular basis. CRM software can allow a firm to be able to take data relating to customers and their preferences and transform it to be able to help the organisation gain financially from it by being able to increase sales from 40% – 50%. The type of data collected by organisations will vary greatly depending upon the business. Information such as personal preferences regarding products, individual tastes, how often products are bought, when products are bought. This information is then filtered through the CRM system and individual plans are formulated in terms of marketing for each customer. Tesco as present have in place their club card system, which is able to monitor the spending patterns of customers. This information is then used by Tesco to target specific customers with offers relating to the types of products they have purchased. By targeting specific offers at specific customers, Tesco is forming a unique relationship with that customer and allows the customer to feel as though they are valued.

The Budgeting Exercise

The budgeting exercise allowed for us within our groups to be able to understand the various areas that need to be taken into consideration when budgeting. The exercise helped gain a greater understanding of the importance of ensuring that budgeting is done correctly and the potential benefits it could bring. The exercise looked at being able to budget for a web campaign and overall marketing for Wines of Uruguay (WOU). The exercise allowed for a greater understanding of the limitations that face many organisations today in a financial sense and also the best way to go about ensuring that funds are spent responsibly.

Through the exercise we were able to understand that budgeting to a certain degree involved some guess-work with regards to the exercise. We as a group were in a position where we did not have any figures or prices at hand relating to various marketing tools so had to guess at the potential price of various activities. The exercise proved how hard it was to be able to correctly or to a degree formulate the correct expenditure for a given period. The gains of doing this successfully could be huge with the business succeeding and benefiting from increased sales while incorrectly formulating budgets could lead to loss of jobs as well as a poor return for the money spent.

E-Procurement

6 Comments

Benefits of E-Procurement

According to Chaffey(2009,pg 289), various things can be bought by a business, it could be stationary for the office, raw materials for manufacturing company etc. E-Procurement assists in the purchase and resell of goods, it’s a direct line between the purchaser and a web based catalogue. If WOU is able to implement E- Procurement customers and employee can order for wine from web sites. WOU will be able to have full control of the budget and inventory, increasing accuracy delivery and payments of wines of WOU.

IT components of E-Procurement

Website: it is the most fundamental and most efficient tool for E-Procurement. Almost all the information could be shown via the website. Some questionnaires or surveys can be done through the website as well. It is convenient to get feedback from customers.

Database: it could be present and collect the data from the website. For example, sale trends can be foreseen and compared to the sale data of the last few years. You can avoid the possibility of the factory producing too much and can manage demand as well.

Security-system: a reliable security-system is significant for e-procurement. Most of the time e-procurement involves the information of bank details. If the information was hacked then there would be problems in terms of reputation and legal.

Tools of communication: such as email and mobile phone, can make communication more effective between the supplier and the retailer.

Manage by using software: there is several software for e-procurement which could simplify the process of e-procurement and apply certain functions to help evaluate and analyze the efficiency of suppliers thereby getting more useful market quotations.

The Beer Game Experience

Our group was tasked to simulate a part of the supply chain, in our case being a distributor of the beer. Our role was to be middlemen between the wholesalers and the factory that produces the beer.

Each week an order would be passed up from the retailers to the wholesalers, who would in turn make an order to our team. We would then decide how much stock to order from the factory. The turn-around time for delivery of orders is 2 weeks, whereas orders only require 1 week. This rule of the game required our group to strategise how we can best maintain the minimum amount of stock (for reasons of cost), and at the same time to ensure that we can deliver the amount ordered from the wholesalers (there is a penalty for backorders or unfulfilled orders).

In practice, we found this balance really difficult. The first few weeks of the game went by without much difficulty, as the orders coming up from the wholesalers were not substantial and we could find the necessary stock to pass on to them. However, we were taken aback when an order came up for 40 units of stock on one single week that we were unable to fulfil. This created a backlog of orders and when we passed on the order to the factory, they too were unable to cope and produce enough beer in time. Over time, this backlog posed serious problems to the supply chain, as we were unable to satisfy the orders from the wholesalers and eventually, the retailers and the customers. There was also a ‘snowball’ effect, where we were perpetually backlogged as more orders kept coming in and we were struggling to fulfil our initial orders.

Some of the learning points on the supply chain are that firstly, communication is key in the supply chain. One rule of the game when it was played was that all the groups in the chain were not allowed to communicate except for passing notes on the quantity of orders and delivery. This posed problems, as we had no idea what was going on at the wholesalers and retailers. We had no possibility to predict and find out what their current stock of the beer was to aid in our forecasting of orders to the factory.

Secondly, making a small mistake can have large consequences in a supply chain. The sudden large order from the wholesalers threw our plans into disarray and we never recovered from it. We tried our best over the weeks after that to improve, but we were still backlogged and struggling to cope with our initial mistake. In the real world we probably would have gone bust.

Wine Procurement Competition Experience

The second simulation game was very similar to the beer game, but involved bidding for contracts with regards to wine. The game looks at monitoring output with regards to wine and the possible returns from adjusting the price of wine. The game involved two choice of wine, which were priced at £5 and £15.

The game involves deciding how many bottle each group can provide and the price that they are willing to offer it for, which can be any price possible. The aim is to offer a unique enough price for a certain amount of wine. The wine demand in terms of numbers are not known in advance so it is very much about anticipating possible requests and monitoring the offers of all other teams. The buyer will then weigh up all offers and decide which is the best offer for him, which is usually the cheapest offered, but not always as it will depend on the quantity needed so can result in more than one groups’ bid being accepted.

The game helped understand the importance of anticipation and analysis with regards to competitors. The game also allowed for all groups to learn about the slim margins with regards to adjusting price and understanding that a difference as small at 50p can either win or lose a potential contract.

Over the course of a longer game it would also allow us to follow demand and learn in terms of bidding patterns. The information will help tighten future bidding and allow for concentrated pricing.

The game teaches:

- Anticipation with regards to future contract offers

- Monitoring rival bids

- Understanding pricing

- Adjusting pricing to win contracts

- Communication with regards to ensuring that other competitors cannot hear group plans

Make the Most of Supply Chain Analytics

1 Comment

By Andrew Hines

Dell, Apple, your local grocery store — all these companies share a common concern: supply chain management. From the initial forecast to final delivery, coordinating activities in a supply chain is a big challenge. But if you do it right, the ROI is huge. Usually the challenge boils down to building the right capability in your organization, which means having the right people and the right tools.

Investing in a new software package and a team of supply chain analysts, however, is a serious undertaking, and there’s no one-off solution. Should you focus on forecasting, inventory optimization, logistics, supply chain simulation? An article by Sridhar Tayur in Supply & Demand Chain Executive points out that inventory optimization is probably the best place to start, and gives a $1 billion example to back it up:

Given the enormous benefits at stake [by optimizing inventory], it’s no surprise that a recent survey by Aberdeen Group places inventory management software at the top of the list for supply chain technology investments. Within that category, the highest priority is clearly multi-stage inventory optimization, which generates optimal inventory levels for each item across each of the stages or tiers within an organization’s supply chain network. More than 80 percent of respondents cited multi-stage inventory optimization as a top priority, nearly twice the number who named any other type of inventory management technology. […]

A case in point is Deere & Company’s Commercial & Consumer Equipment Division, which implemented a solution to optimize inventory levels for more than 300 commercial and consumer equipment products held at 2,500 North American dealer locations, plants and warehouses. To do so, the software considers 52 million variables and 26 million constraints. In four hours each week, the system generates optimal targets [target inventory levels] that have enabled Deere to reduce inventory by more than $1 billion, while significantly improving on-time shipments from factories and maintaining customer service levels at 90 percent or better.

The $1 billion in reduced inventory means that Deere is now free to invest that much cash elsewhere in the business. With that in mind, a few million dollars doesn’t seem like too much to invest in optimization software and supply chain analysis team.

http://blogs.bnet.com/intercom/?p=537&tag=content;col1

Improving the Labelling aspect of wine production with IT

4 Comments

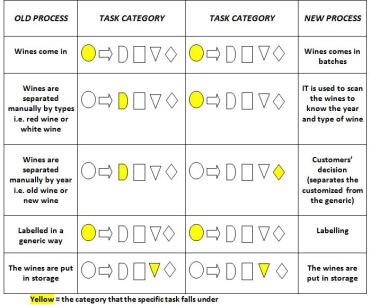

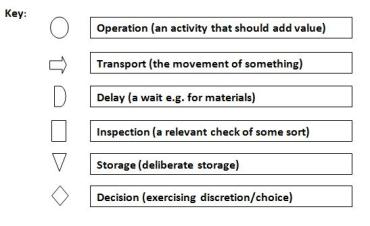

We as a group have decided to improve the labelling aspect of wine production with the use of information technology. We have assumed certain ways in which companies currently go through the process of labelling their wine and have out forward how this can improved with the use of IT to add value and allow wine producers to be more efficient in terms of the running of their processes.

OLD PROCESS

OLD PROCESS

The old process is assumed as being very time-consuming and will not allow for efficiency or saving of resources. The old process is assumed as being very rigid and utilising very little information technology to label wines accordingly. The stages are:

- The wine will arrive from the foiling stage

- The red and white wines are then separated by hand

- The wine is then organised into the year in which it was produced if necessary

- Following this, the wine is then sent through the labelling machine to be labelled with generic labels to differentiate between red and white

- The wines are then stored until they are ready to be shipped

NEW PROCESS

The new process will add value in many ways and will allow a wine company to improve upon their current processes through the use of information technology and will also add as another possible way of improving sales. The new process will utilise IT as well as allow wine producers to offer customised labelling in order to attract customers and improve the chances of the customer being happy and right. The stages of the new processes are:

- The wine will appear from the foiling process in batches with a batch label to specify year

- The system can then scan the batch label before determining what type of wine it is (red/white)

- Next, any customisation can take place as label templates have already been installed into the IT system

- The customer can decide to have as many bottles as necessary labelled with their own choice of words (names, dates etc)

- The system can then be programmed to label only a set amount of bottles according to the customer order before continuing to label the rest as normal with the generic template

- The wines are then sent to storage